Genano Catalytic VOC Abatement

A gamechanger in VOC abatement

Significantly lower carbon print

Fast installation

Superior Effectivity in a compact size

We can help you overcome these challenges:

Cutting VOC emissions

New regulations to reach

High energy costs

Odor emissions

Reaching sustainability goals

The smart Genano VOC Abatement system relies in catalytic oxidation resulting in significant money and time savings for your company – only byproducts being a lower carbon footprint.

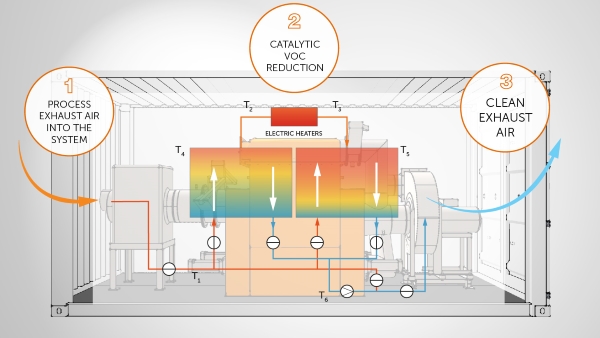

The Innovative Catalytic Oxidation

Volatile organic compounds (VOCs) are chemicals that constitute one of the primary elements of air pollution in a wide range of industries – especially in processes that use large amounts of solvents or produce carbon monoxide, or odors. VOC emissions are significant greenhouse gases, and therefore regulated by national and European directives.

Genano VOC series are state-of-the-art compact catalytic VOC and odor abatement systems for energy efficient control of VOC waste gases. It fulfills the requirements of the EU VOC directive.

Durability

Long lifetime due to lower operation temperature

Efficiency

High purification efficiency

Functionality

Compact size and easy to move

Automation

Adapts automatically to airflow and concentrations

Optimization

Low maintenance needed

Sustainability

Small carbon footprint

Why catalytic oxidizer is the most sustainable VOC abatement choice

No harmful byproducts like nitrogen oxides

After a catalytic oxidation we will only find vapor (H2O) and Carbon Dioxide (CO2).

Oxidizer’s exhaust air is below the EU VOC limit values

Outcoming air is free of VOCs and can be exhausted directly to outside air.

Saves energy

The operating temperature is nearly 500°C lower compared to traditional methods.

Life cycle

The low operation temperature causes significantly less thermal stress to the constructions of the oxidizer, which directly increases the life-cycle of the oxidizer and decreases the maintenance costs.

The Use and Installation of Genano VOC Abatement system

Genano’s catalytic oxidizers are fully automatic, adapting to different flow rates and different VOC concentrations.

The VOC oxidizer has been designed to enable installation outdoors or inside the production plant if preferred.

The installation area required is minimum and doesn’t interfere with other existing installations.

How can we help you?